LINX Line Scan X-ray Cameras

LINX detectors are an expandable off the shelf modular system for inspecting objects transported on a conveyor belt using XRT.

Sens-Tech supplies a range of linear X-ray sensors which use XDAS acquisition and signal processing electronics to provide an array of any required length.

Single and dual energy detectors with pitches of between 0.4mm are 2.5mm are available for low to high energy applications. X-rays are detected using silicon photodiodes and scintillation materials from a wide a range of materials. GOS, ZnSe, CsI(Tl), CdWO4 and other more exotic chemistries are available.

Our product specialists with decades of experience will help you select the best scintillators for your application. Materials for all photodiode sizes are available and in stock to cover the X-ray energy range of 20keV to 300keV.

LINX units are housed in an aluminium Farraday cage with lead screening to protect the electronic components from radiation damage. The unit has a collimator with a carbon fibre window, so that only a narrow X-ray beam can reach the detector, reducing scattering and improving image quality.

Specifications and useage

KEY FEATURES

- Array lengths up to 4 m

- 0.4 -2.5mm detector pitch

- Single and dual energy

- Range of scintillator types

- Simultaneous data acquisition and read-out

- Short integration time down to 43us

- 31 gain steps from 1.875 pC to 60 pC

- Continuous or external trigger

- GIGE interface to workstation

DESCRIPTION

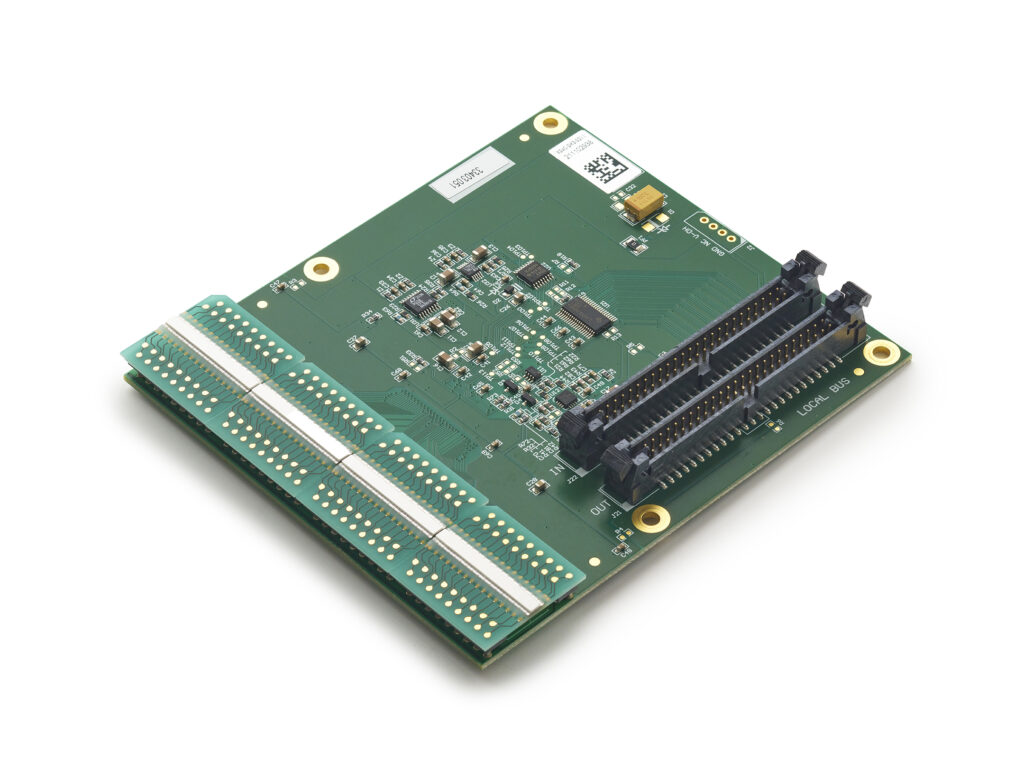

The LINX-V3 series are linear single and dual energy modular high speed linear X-ray sensors. These industry leading high perfomance detectors are built up of Sens-Tech XDAS DH (Detector Head) and SP (Signal Processing) boards to provide an array of any length. The gain for each DH board can be set separately and a huge number of other parameters are available to give the maximum imaging control.

The XDAS electronics are housed in a perfectly formed aluminium alloy box of modular construction with a stainless steel lid. As well as lead screening to protect the electronics from radiation damage the housing forms a perfect Farraday cage keeping interference out. The unit has a collimator with a carbon fibre window, so that only a narrow X-ray beam can reach the detector, reducing scattered radiation and improving image quality.

PRINCIPLES OF OPERATION

X-rays are detected using a wide range of scintillator chemistries and thicknesses and photodiode array sizes suitable offered to cover the energy range of 20keV to 300keV.

Data acquisition time can be set from 50µs to 50ms subject to the active length and data is sampled in a 16-bit format. The read-out rate from the detector to a client workstation via GIGE ethernet is up to 48MB/s.

APPLICATION/S

LINX detectors have been used by hundreds of customers for any XRT application; here are some examples:

- Food – Foreign object detection

- Food – Seperation for yield

- Waste – Rare earth metal seperation

- Mining – Mineral sorting

- Wood – Foreign object detection

- Wood – Quality control

- Steel – Thickness gauging

- Security – Vehicle scanning